|

RockAuto now carries S.A. Gear Timing Components. S.A. Gear is family owned and has been manufacturing timing chains and sprockets in the U.S.A. since 1986. For ease of ordering and installation, S.A. Gear also offers a comprehensive line of complete and partial Timing Chain & Component Kits, so you can be sure you have everything you need when replacing your timing chain. All S.A. Gear products are ISO 9001 quality certified and undergo extensive in-house testing. Find S.A. Gear Timing Components and more in the "Engine" category of the RockAuto.com catalog. | |

| |

| |

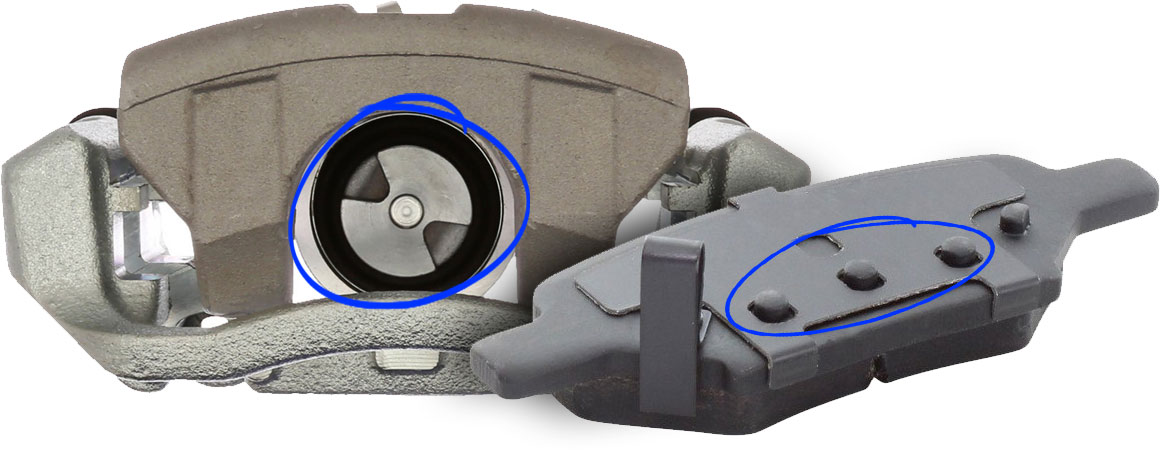

I recently replaced the front and rear brakes on my son's 2009 Pontiac G6 when I snagged a great deal on some wholesaler closeouts! The front brake replacements went quickly and easily, and then I turned my attention to the rear. On this Pontiac, the rear brake calipers cannot just be squeezed back into place. Nope, they have to be turned while squeezing the piston back in. I bought the tool needed from RockAuto as well. I went about it on a hot sunny day and thought everything was ready to go, but for some reason I couldn’t get one of the rear calipers back onto the new rotors. Something was stopping it. Well, after about 40 minutes of struggling and looking, it finally hit me. With these particular rear brakes you must line up the groove in the caliper piston with the set of rivets on the brake pad otherwise they will not properly fit. Needless to say, I figured it out in the heat, and the other side only took about half as much time to complete. Look for the obvious and simple error first! Chris in Rhode Island  Caliper Piston Grooves & Brake Pad Rivets |

|

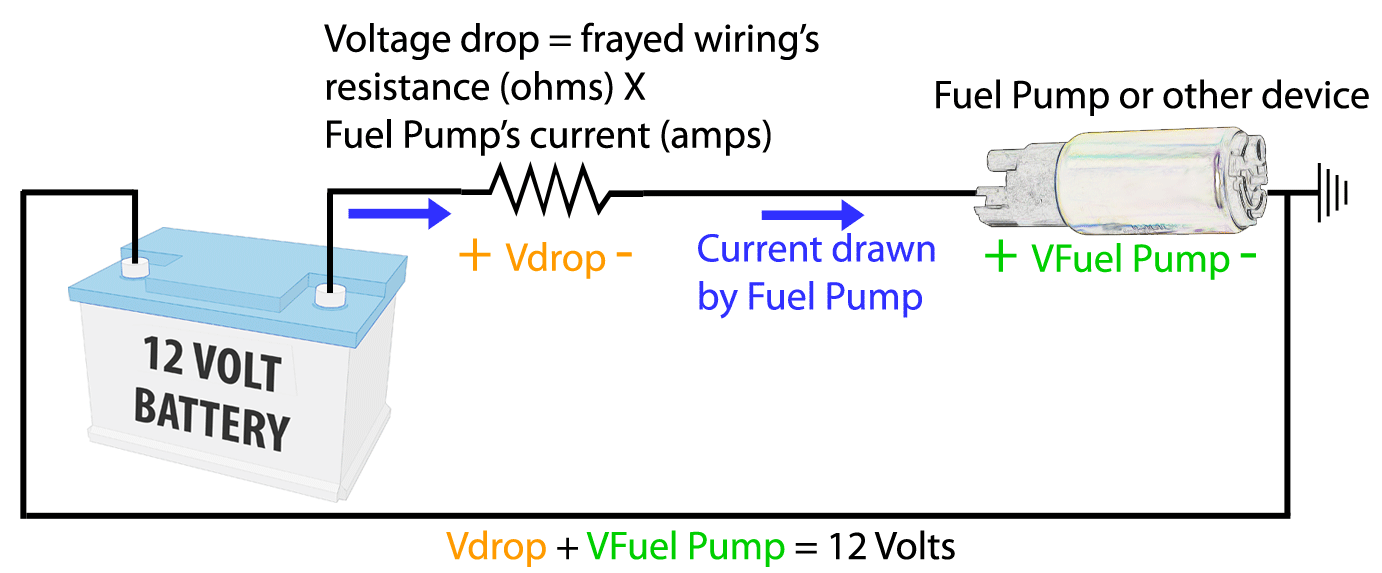

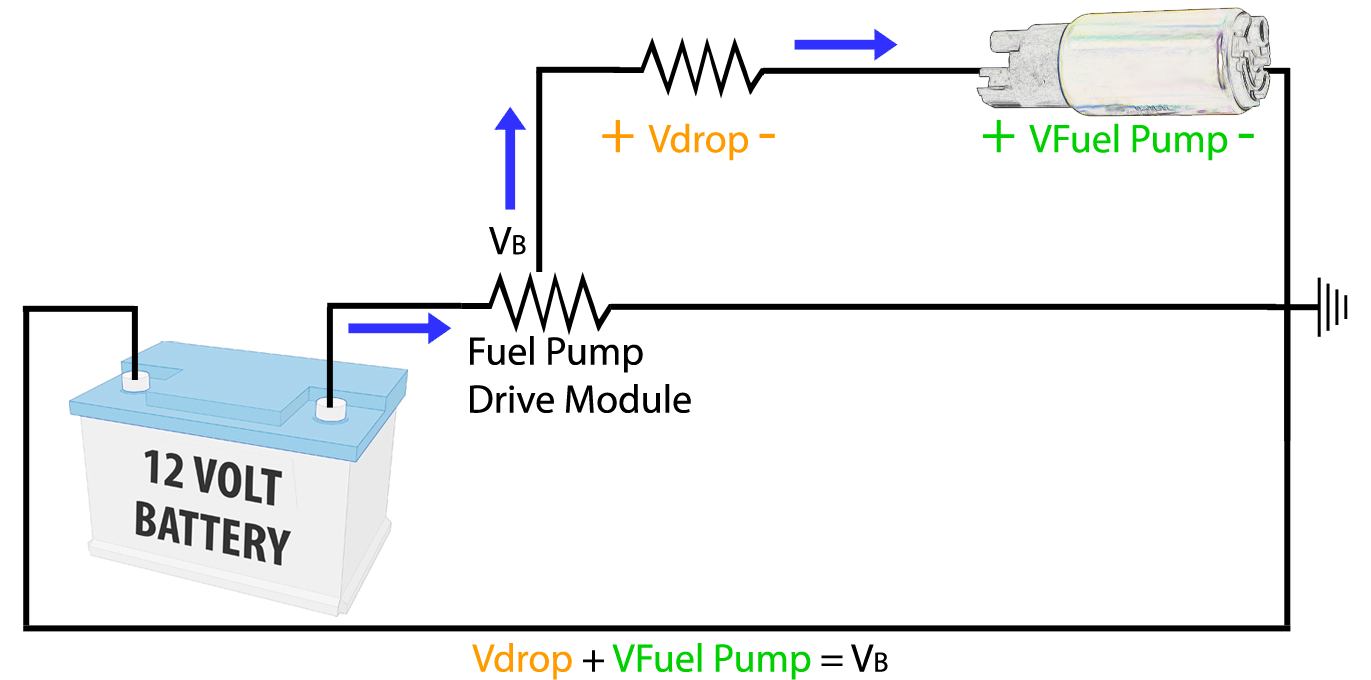

Melted electrical connectors, frayed wiring, worn solenoids and corroded grounds all add resistance to an electrical circuit that can cause a voltage drop; depriving a downstream fuel pump, water pump, power steering assist motor or other electric part of the voltage it needs to operate correctly. I watched a recent trade journal video that explained how important it is to measure voltage at an operating fuel pump's plugged-in connector rather than measuring voltage or using a test light at an unplugged connector. Ohm's law says voltage equals current multiplied by resistance. A fuel pump might draw 5 amps of current while a test light or multimeter applied to an unplugged connector might only draw 0.02 amps. Even a badly frayed wire with a lot of resistance will not waste (drop) much voltage with only 0.02 amps flowing through it. Let's say frayed wiring adds 1 ohm of resistance to the fuel pump circuit. If the fuel pump is attempting to draw ~5 amps of current then the "bad" voltage wasted or "dropped" by the frayed wiring might approach 1 ohm X 5 amps = 5 volts. If the battery voltage is 12.5 volts then the voltage measured at the fuel pump's plugged-in connector will be only ~ 7.5 volts (12.5 volts minus the 5 volt voltage drop).  If instead the voltage was measured at the fuel pump's unplugged electrical connector, then the only current in the circuit would be the ~0.02 amps drawn by the test light or multimeter. The frayed wiring 1 ohm of resistance would only cause a 1 ohm X 0.02 amps = 0.02 volts voltage drop. That insignificant drop in voltage might make the mechanic come to the wrong conclusion that the wiring is OK and the fuel pump must be bad. The example fuel pump circuit discussed in the trade journal video was designed to provide the fuel pump with 12 volts continuously or as 12 volt pulses. Some fuel pump circuit designs instead use "good" voltage drop to control the speed and output of the fuel pump (or other device). For example, the computer might intentionally dial down voltage to slow the pump when the engine is idling. A "Fuel Pump Drive Module" (listed under "Fuel & Air" in the RockAuto.com catalog) in the circuit may indicate the vehicle varies voltage to the fuel pump. In that case, it may actually be useful to measure the voltage at the connector unplugged from the fuel pump. This might help establish the approximate baseline voltage the computer intended to provide to the fuel pump. Then measure the voltage at the connector with the fuel pump plugged-in to see if there is a voltage drop from that baseline voltage.  It makes it harder to get useful measurements with just a multimeter if the computer sends the fuel pump 12 volts at startup and then immediately lowers the voltage to some new level once fuel pressure is established. In that case it might be useful to see if the voltage at the fuel pump changes with engine rpm. If it never gets close to 12 volts even at higher rpm, then that might indicate there is unwanted voltage drop limiting the maximum voltage available to the pump. Once it is established that there is "bad" voltage drop then it is time to move upstream in the circuit looking for damage, unusual heat or unexpected voltages occurring across sections of wiring, connectors or other components that should normally have close to zero electrical resistance. Tom Taylor, To read more of Tom's articles, click this link and choose from story titles on the Newsletter Archives page. |

|

|

|

Here is my 1969 Ford Torino GT Formal Roof, with a 351W, auto trans and bucket seats with console. I have owned it since 2015 and have used RockAuto to replace many of the original parts since then. It has been repainted once, but the majority of the parts, interior and trim were original when I got it as it sat in storage from 1988 until 2015. It had about 58K miles on it when I purchased and it's now ready to turn 66K miles. Parts from RockAuto have included: Fuel Pump / Starter & Solenoid / Water Pump / Suspension / Headlights / plus a lot of smaller miscellaneous items. Thanks! |

Share Your Hard Work & Stories | |

|

Your Hard Work Do you purchase parts from RockAuto? If so, RockAuto would like to give you the opportunity to have your car or truck possibly featured in one (or occasionally more) of our publications such as the monthly newsletter, collector magnets or other commercial use. New, old, import, domestic, daily driver, trailer queen, classic, antique, we want to see them all! For submission instructions and tips for taking pictures of your car, please visit our Photography Tips & Submission Info page. Your Most Infamous Auto Repair Blunder Use your woe to help others avoid similar mistakes. Please email your story to marketing@rockauto.com. Include your mailing address and if you would like a RockAuto Hat if we publish your story. See the Hats under Tools & Universal Parts in the RockAuto catalog. The story will be credited using only your first name and your vague geographic location (state, province, country, continent, etc.) so you can remain semi-anonymous! | |